It has been a busy few years in sport for gcp Chartered Architects, particularly when it comes to cricket.

We are continuing to support the England and Wales Cricket Board’s (ECB) Urban Cricket Centre Initiative, a corner stone of Inspiring Generations 2020-24, the game-wide five-year strategic plan to grow cricket in England. This initiative, which is being piloted across the country, looks to create new cricket facilities in densely populated urban areas where access to traditional facilities are limited.

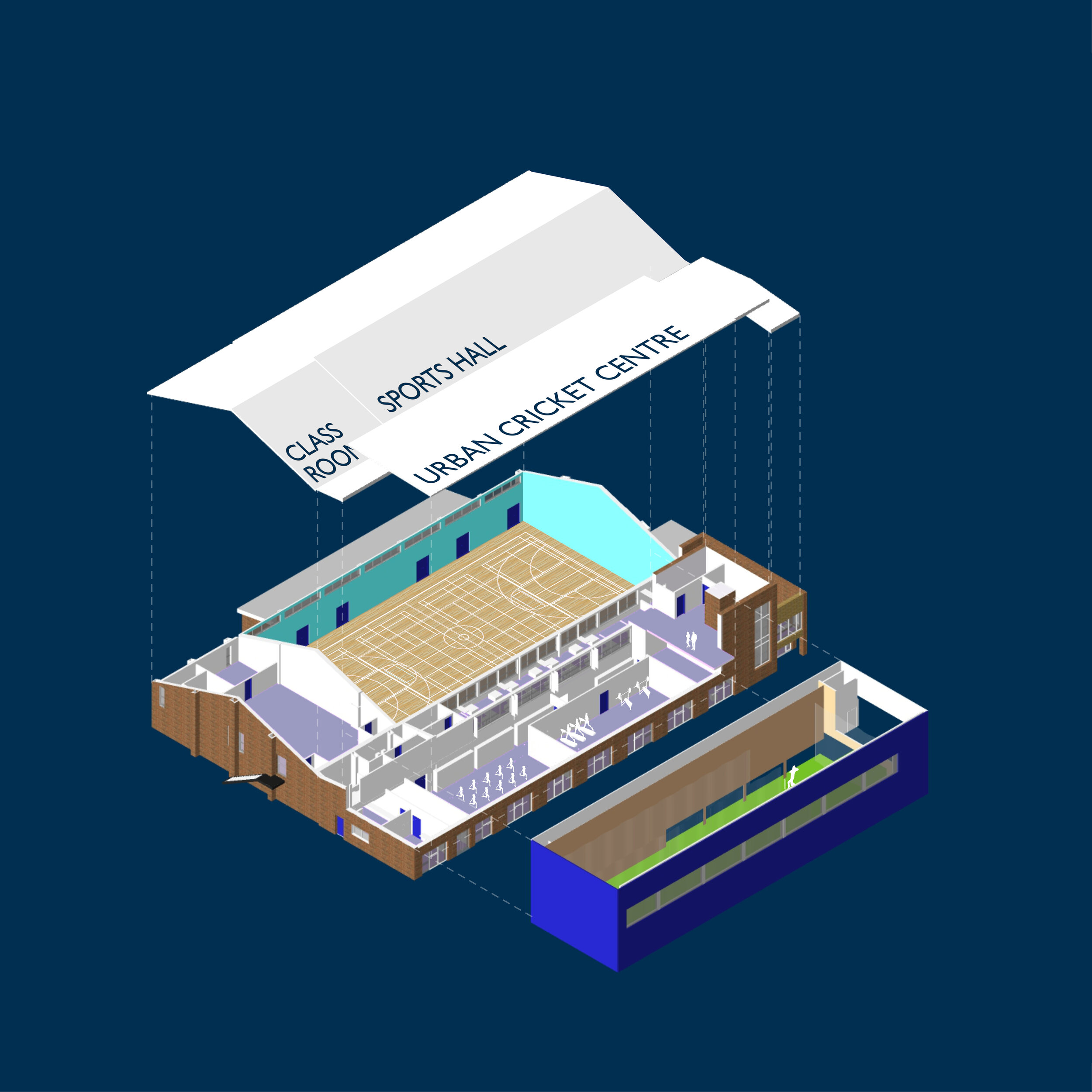

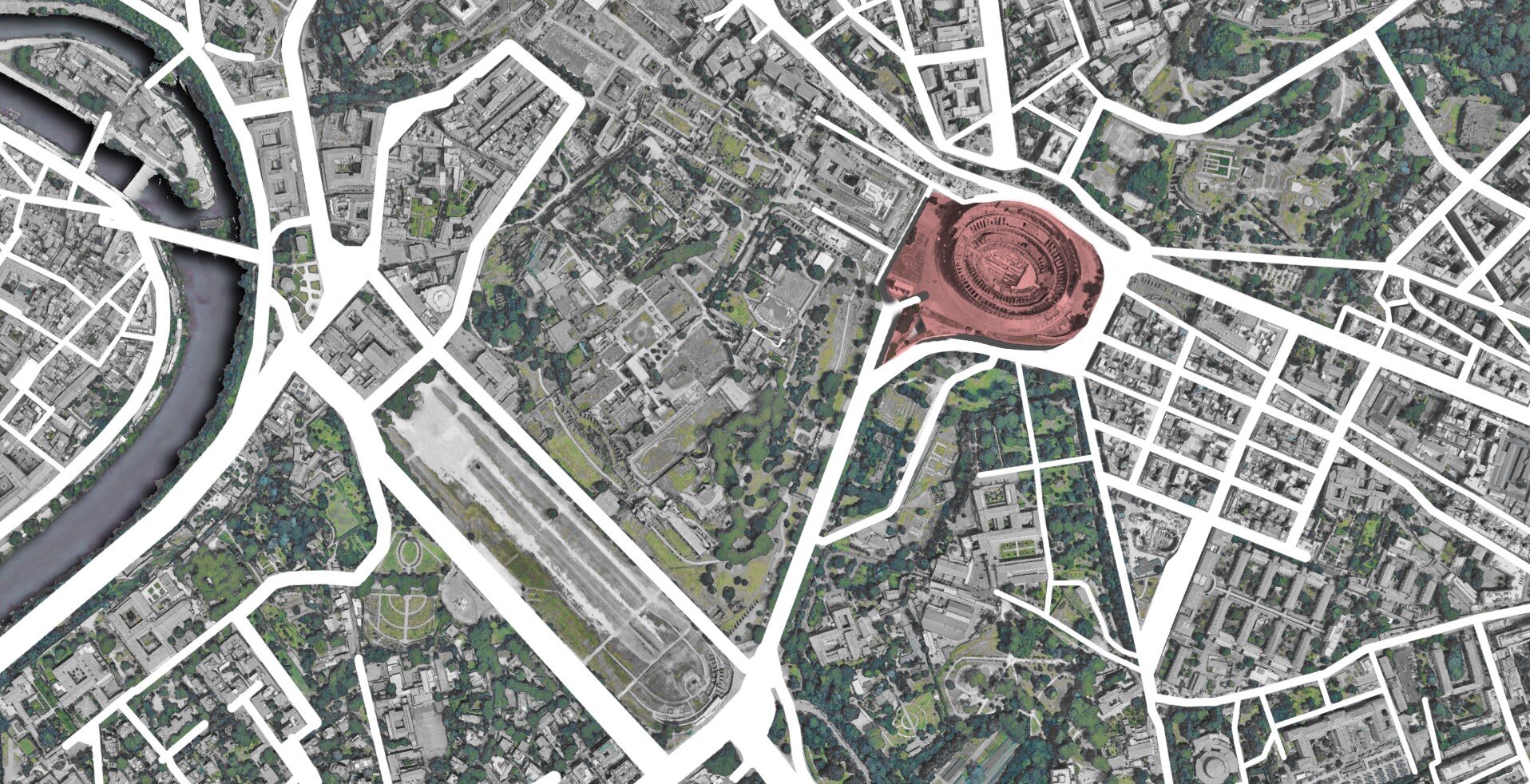

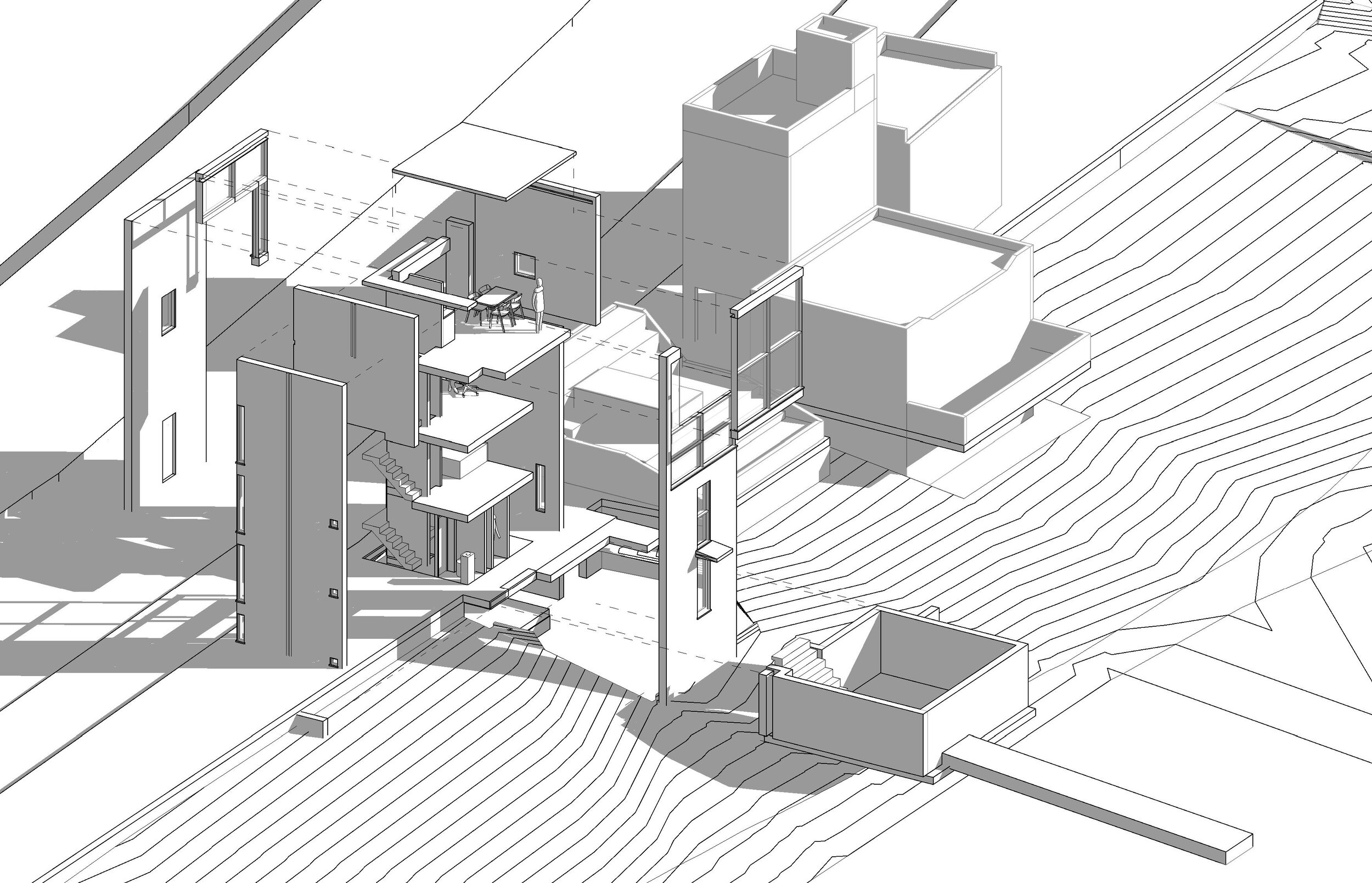

Flyer Axo Phase 2, Bradford

The latest scheme in Bradford will provide two new cricket lanes and additional community facilities that will transform the Parkside Sports Centre into the second ECB Urban Cricket Centre. The first centre at the former Leyton Cricket Ground in East London was opened by Graham Gooch in July 2019 to celebrate the Cricket World Cup.

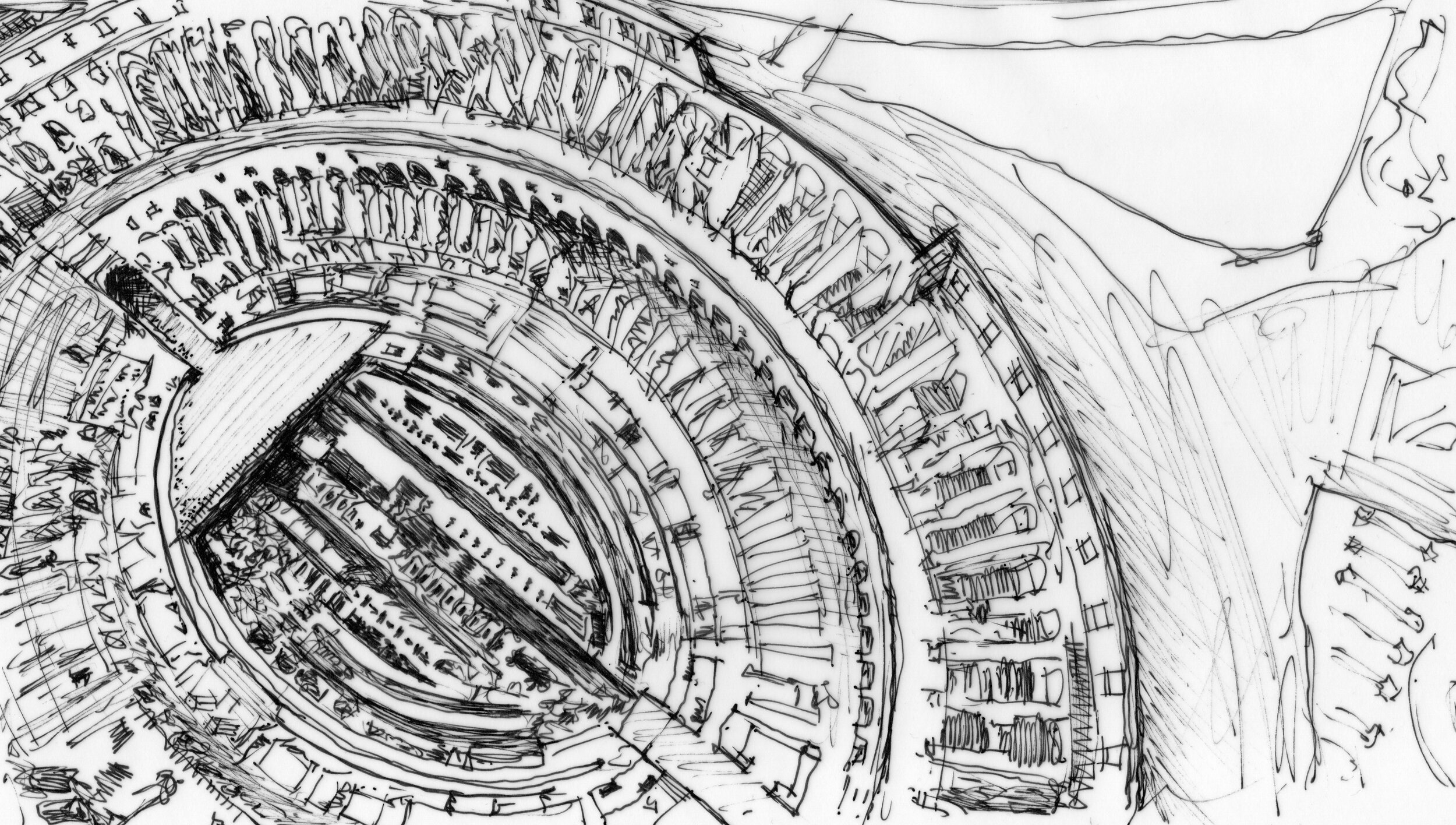

Following on from the Bradford and Leyton schemes, we are currently working on the very early stages a third pilot site, also in northern England. If the pilots prove successful, centres will be rolled out across ten major urban areas in England, with each area supporting a minimum of two cricket centres.

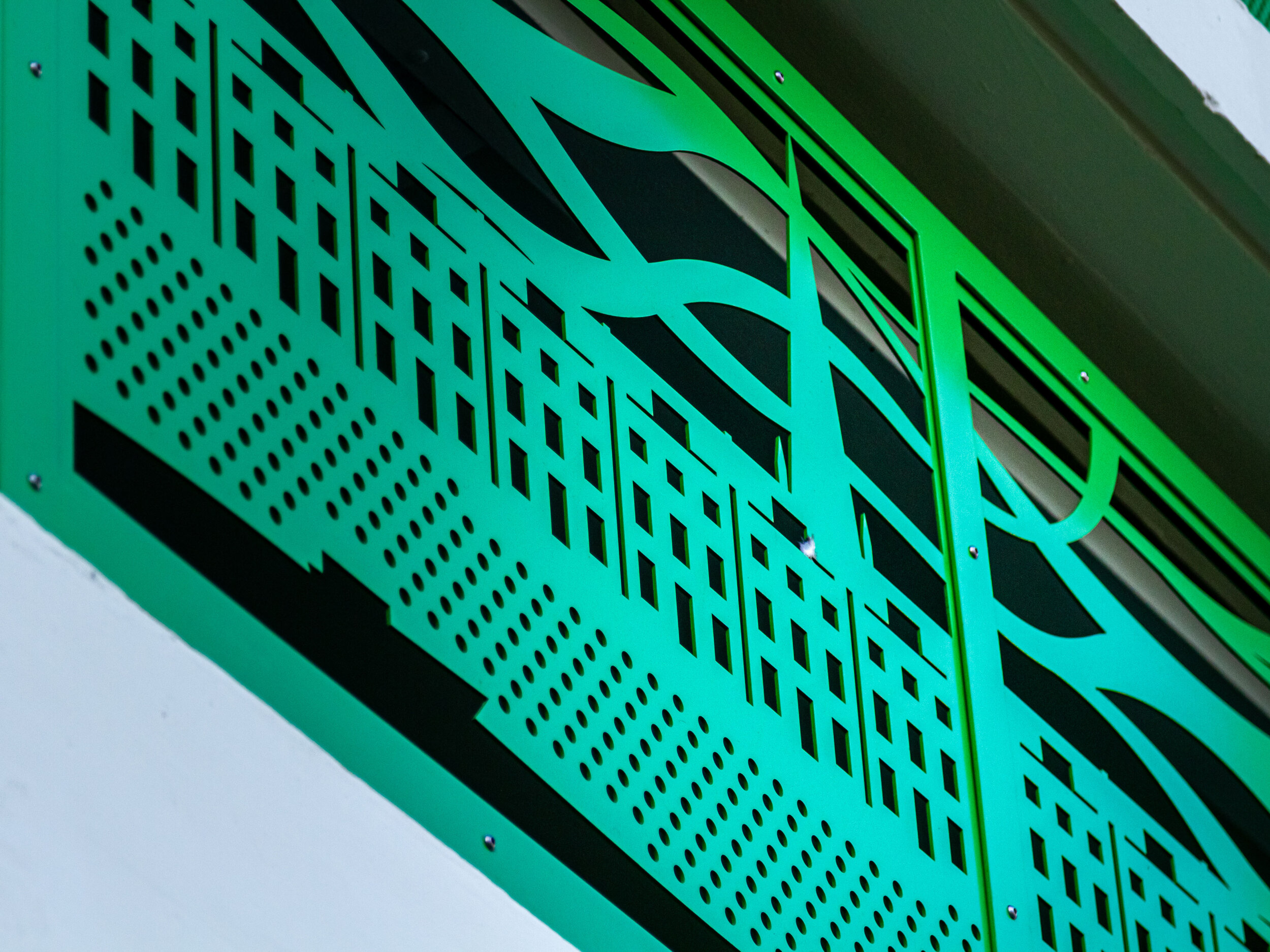

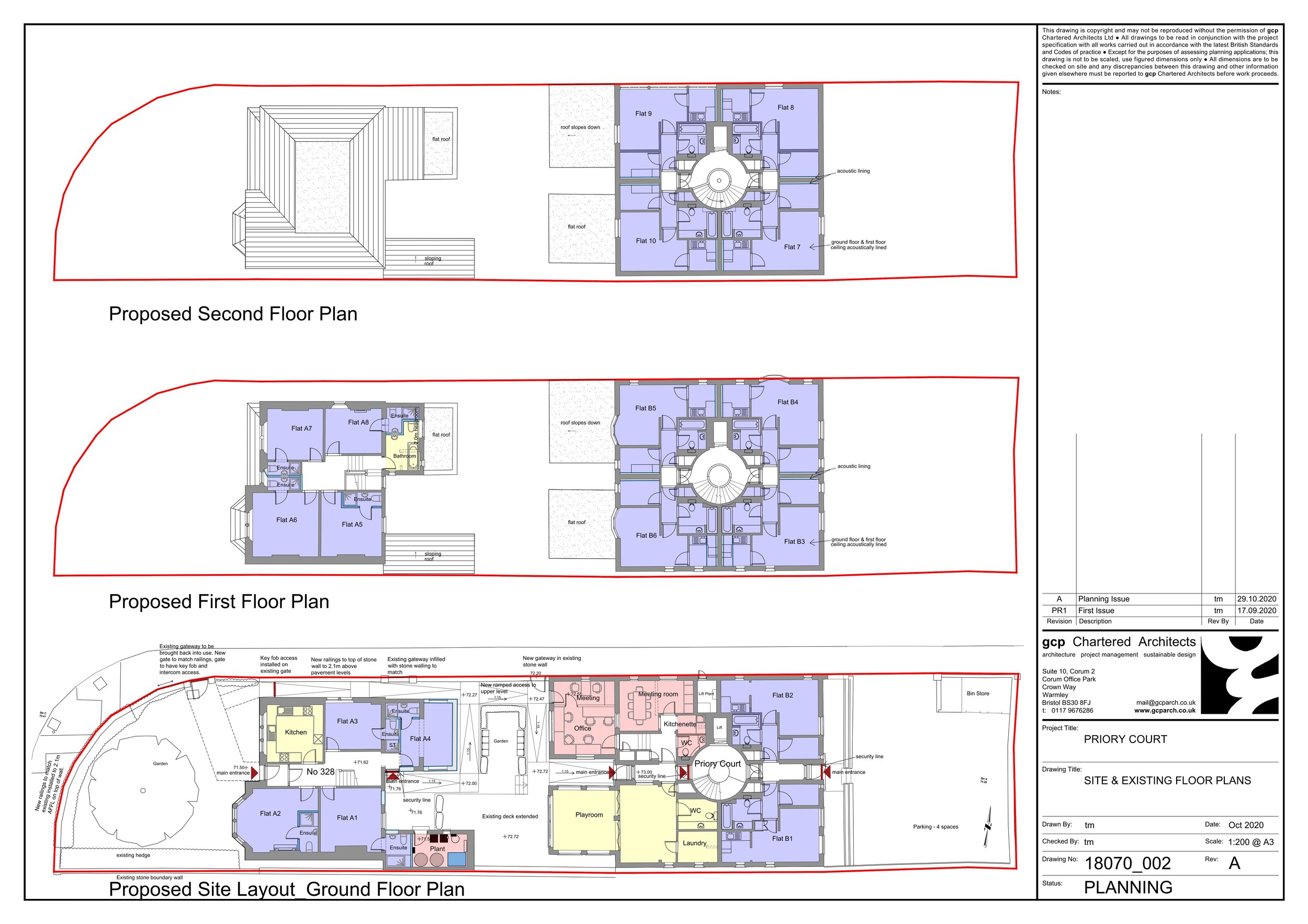

Our most recent commission is working with Middlesex Cricket to develop a new cricket development centre at the William Perkin School in Ealing. In honour of the talented Middlesex left hander who formed a formidable opening partnership with Graham Barlow in the early 1980’s, the centre will be named the Wilf Slack Cricket Centre. This project, to compliment Lords Indoor Cricket Centre, will see the school’s existing multi-use sports hall transformed into a cricket focused facility that also makes provision for badminton and basketball. Designed in exacting standards as defined by the ECB, the Wilf Slack Cricket Centre will promote participation from an early age and lay out clear routes for progression in the both the men’s and women’s game.

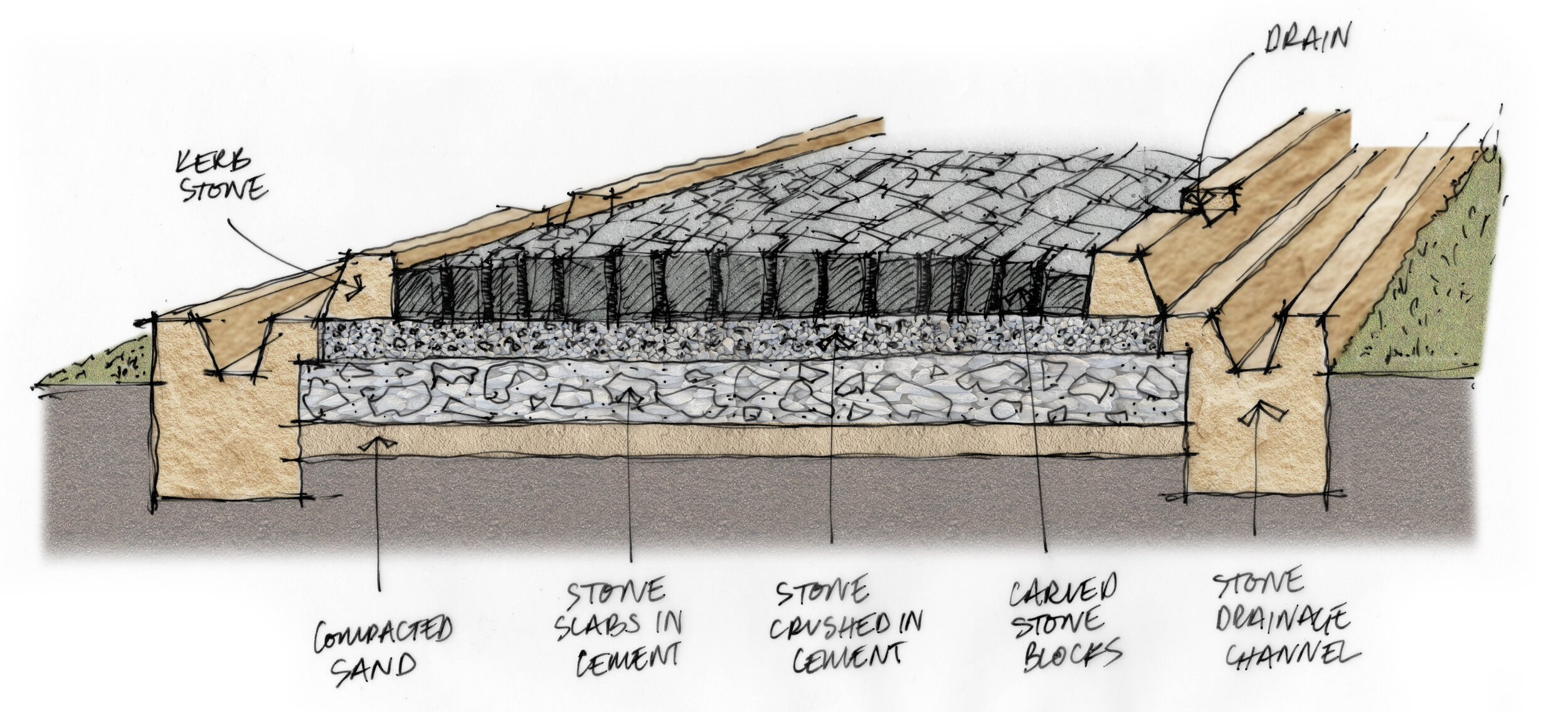

All centres designed by gcp Chartered Architects integrate the latest thinking around netting layout and configuration to maximize flexibility in use and coaching potential, LED lighting to provide the optimum playing environment for the specified sports (particularly cricket), and sports flooring to provide the highest performing surface. All installations are designed to standards defined by the ECB Technical Guidance Notes and tested upon completion to ensure safe playing environments.

For an informal chat about your cricket development project contact gcp Chartered Architects cricket facility design specialists:

Jonthan Platt at jonathan.platt@gcparch.co.uk

Matt Bonney at matt.bonney@gcparch.co.uk

James Pilling at james.pilling@gcparch.co.uk or

Phone 0117 967 6286

Here are some other exciting sport projects undertaken by gcp in the last two years…

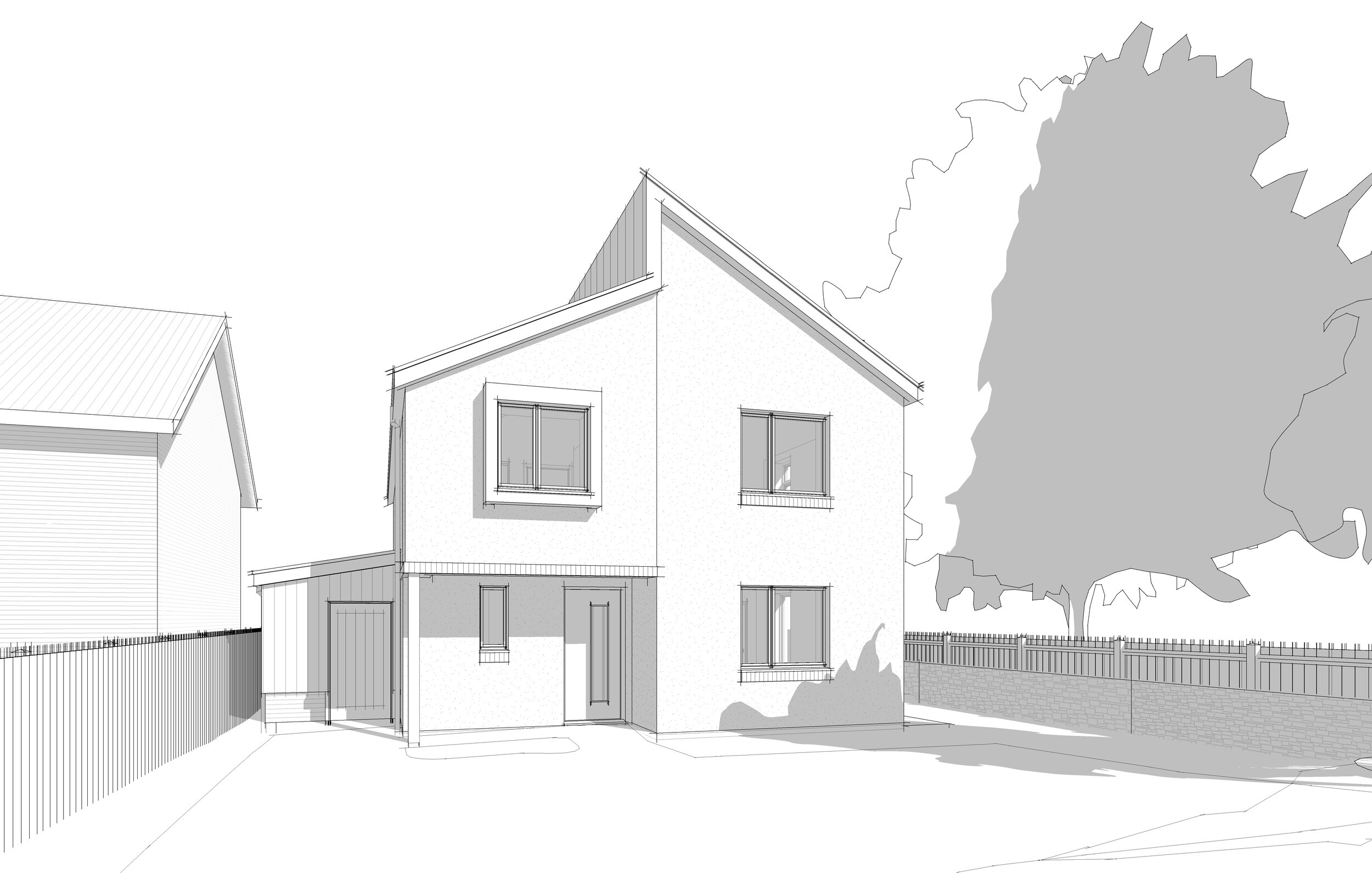

Foundation Park Pavilion, County Ground, Swindon.